Key attributes about Zinc sheet

Industry-specific attributes

| Type | Steel Sheet |

| Thickness | 0.12mm-6mm |

| Coating | Z10-Z275 |

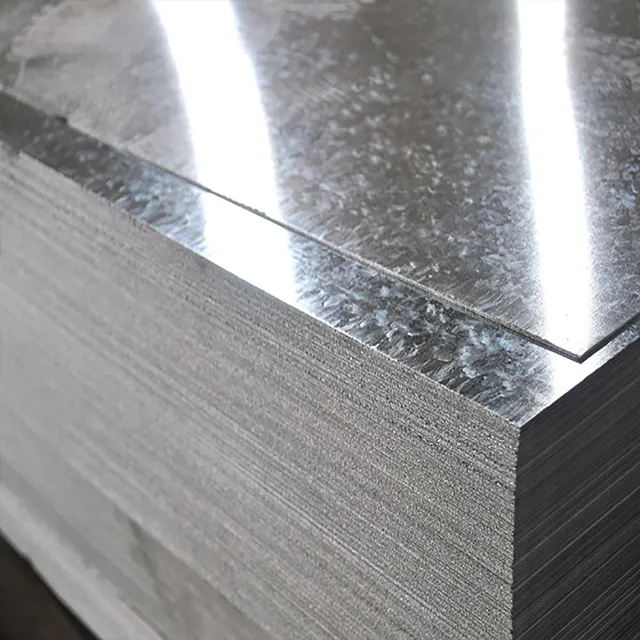

| Spangle Type | Regular Spangle |

| Hardness | Full Hard |

Other attributes

| Place of Origin | Shandong, China |

| Technique | Cold Rolled Based |

| Standard | AiSi, ASTM, bs, DIN, GB, JIS |

| Grade | Dx51d Dx52d Dx53d Dx54d |

| Delivery Time | 8-14 days |

| Brand Name | Kehuan |

| Application | making pipes, cutting sheets, making small tools, making corrugated sheets, making container, making fences |

| Tolerance | ±1% |

| Thickness | 0.12mm-6mm |

| Width | 600mm-1500mm ,or customized |

| Certificate | API , ce, rohs, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Standard | ASTM JIS DIN GB AISI |

| Appearance | Cleaning |

| Product name | Zinc Sheet |

| Place of Origin | Shandong China |

| MOQ | 1 Tons |

| Sample | Avaliable |

| Payment | TT DP LC |

| Technology | Hot Rolled |

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Quality Assurance

Quality Assurance

Certified Inspections

Company Profile

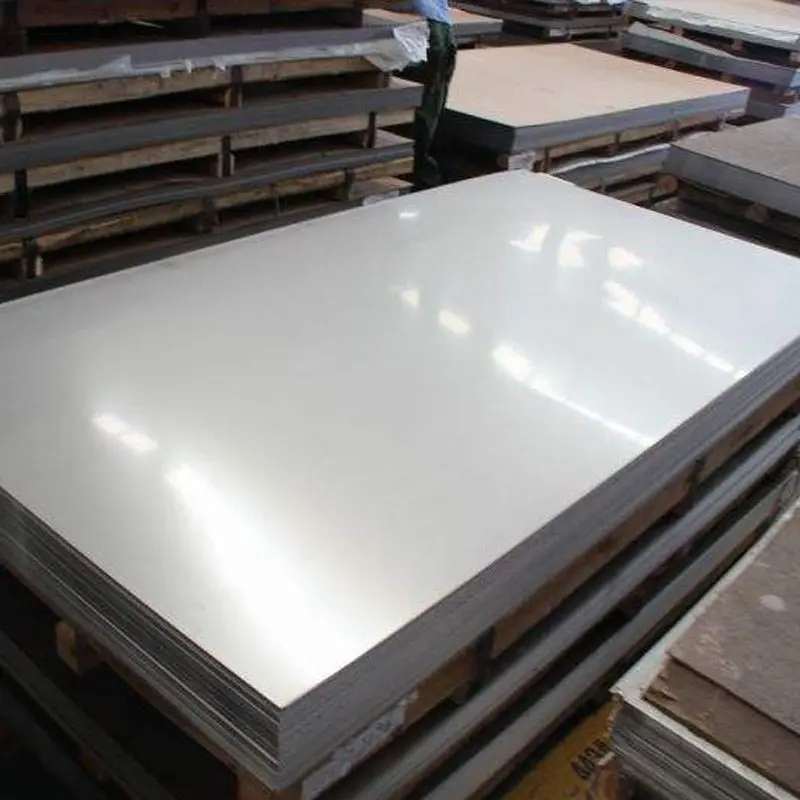

Established in 2011, located in Liaocheng City, Shandong Province

It is one of the largest manufacturers of carbon steel and alloy seamless steel pipes in Shandong Province, China.

Kehuan has four advanced hot rolling production lines Eight expansion production lines and China’s most advanced heat treatment production line.

Interacting with customers

What is Galvanized Steel sheet ?

Galvanized steel sheet is steel that has been coated with a protective layer of zinc, typically through hot-dip galvanization or electroplating. This process enhances the steel’s resistance to corrosion, rust, and environmental damage, making it a versatile material for applications where durability and longevity are critical. The zinc sheet coating acts as a sacrificial barrier, protecting the underlying steel even when the surface is scratched or exposed to moisture, salt, or chemicals.

Manufacturing Process of Galvanized Steel sheet

- Hot-Dip Galvanization:The cleaned steel is submerged in a bath of molten zinc at approximately 450–460°C.A chemical reaction forms a series of zinc-iron alloy layers on the steel surface, creating a thick, metallurgical bond.This method produces a rugged coating with excellent corrosion resistance, ideal for heavy-duty applications like structural steel, pipelines, and outdoor fixtures.

- Electrogalvanization (Electroplating):An electrochemical process deposits a thin, uniform zinc layer (5–25 micrometers) onto the steel using an electric current.This method offers precise control over coating thickness and a smoother surface finish, suitable for applications requiring aesthetic appeal or tight tolerances (e.g., automotive parts, electronics).

- Sherardizing (Less Common):A dry galvanization process where steel is coated with zinc powder in a rotating drum at elevated temperatures, forming a diffusion layer.Used for small components or where liquid baths are impractical.

Advantages of Galvanized Steel sheet

- Exceptional Corrosion Resistance:The zinc coating provides long-term protection against rust, even in harsh environments like coastal areas, industrial settings, or regions with high humidity. This makes galvanized steel suitable for outdoor structures (e.g., bridges, fences), automotive components, and agricultural equipment.

- Cost-Effective Longevity:Compared to stainless steel or other corrosion-resistant materials, galvanized steel offers a lower initial cost while delivering comparable service life. Reduced maintenance needs (e.g., painting, rust removal) further lower long-term costs.

- Mechanical Strength and Versatility:Galvanized steel retains the inherent strength and formability of plain steel, allowing it to be easily cut, welded, bent, or machined into various shapes.

- Environmental Benefits:Zinc is a recyclable material, and galvanized steel can be fully recycled at the end of its lifecycle without losing its protective properties. Hot-dip galvanization also has a lower carbon footprint compared to some alternative coating methods.

- Diverse Surface Finishes:Depending on the galvanization method, the surface can range from a rough, spangled texture (hot-dip) to a smooth, uniform finish (electroplated), catering to both functional and aesthetic requirements.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.Convenient Online

Transparent Pricing

Hassle-Free Maintenance

Certified Industry Specialists

Authentic Materials and Components

Convenient Online Ordering

Why Us

- Unmatched Steel Expertise

- Dedicated to Your Specifications

- Premium Quality Materials

- Simplified Ordering Process

- On-Time Delivery, No Compromises

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.