Key attributes about Roofing Sheet

Industry-specific attributes

| Type | Steel Sheet |

| Thickness | 0.12mm-8mm |

| Coating | Z10-Z275 |

| Spangle Type | Regular Spangle |

| Hardness | Full Hard |

Other attributes

| Place of Origin | Shandong, China |

| Technique | Cold Rolled Based |

| Standard | AiSi, ASTM, bs, DIN, GB, JIS |

| Grade | Dx51d Dx52d Dx53d Dx54d |

| Delivery Time | 8-14 days |

| Brand Name | Kehuan |

| Application | making pipes, cutting sheets, making small tools, making corrugated sheets, making container, making fences |

| Tolerance | ±1% |

| Thickness | 0.12mm-6mm |

| Width | 600mm-1500mm ,or customized |

| Certificate | API , ce, rohs, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Standard | ASTM JIS DIN GB AISI |

| Appearance | Cleaning |

| Product name | Roofing Sheet |

| Place of Origin | Shandong China |

| MOQ | 1 Tons |

| Sample | Avaliable |

| Payment | TT DP LC |

| Technology | Hot Rolled |

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Quality Assurance

Quality Assurance

Certified Inspections

Company Profile

Established in 2011, located in Liaocheng City, Shandong Province

It is one of the largest manufacturers of carbon steel and alloy seamless steel pipes in Shandong Province, China.

Kehuan has four advanced hot rolling production lines Eight expansion production lines and China’s most advanced heat treatment production line.

Interacting with customers

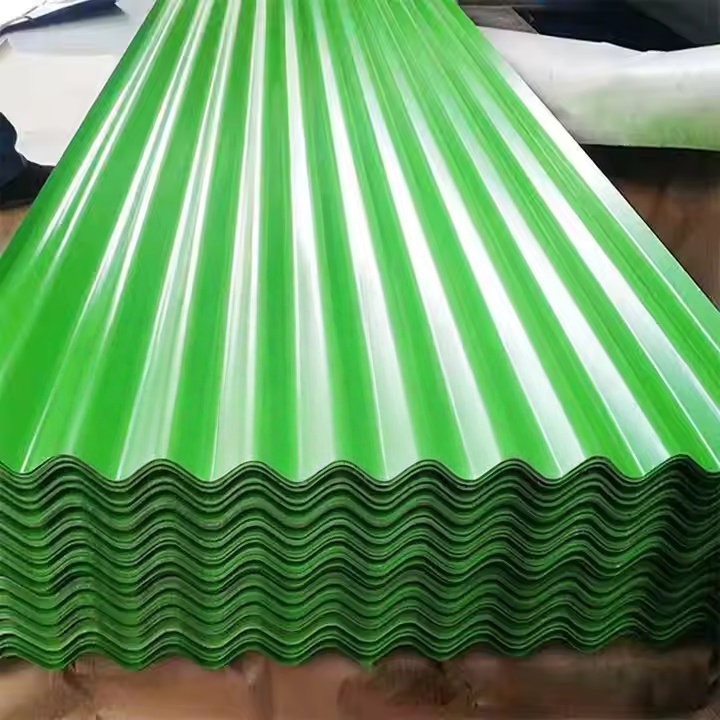

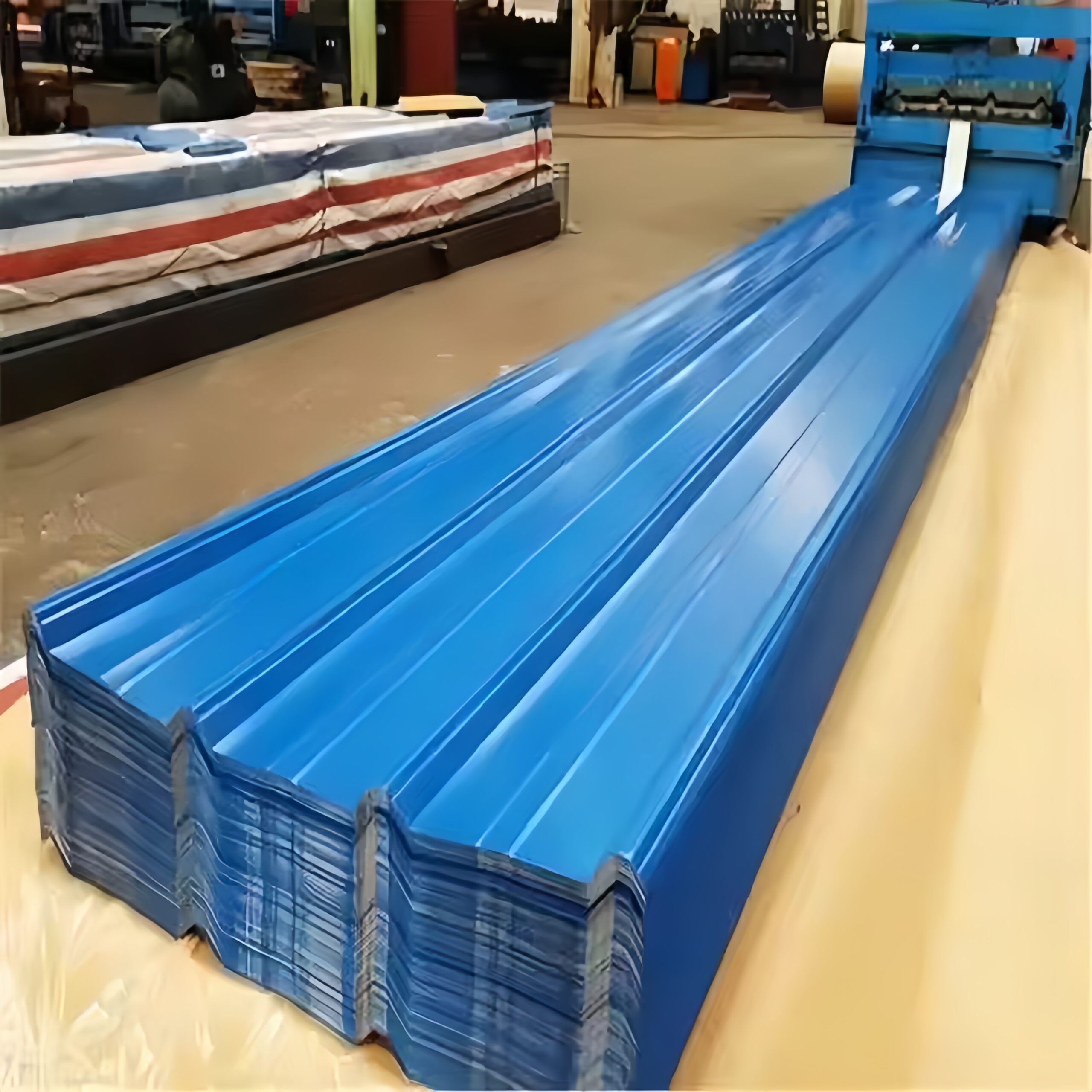

What is Roofing Sheet ?

Roofing Sheet is a type of steel product with a surface coated in organic pigments or polymer films, providing both decorative and protective properties. The coating is applied through a continuous rolling process, combining corrosion resistance with customizable colors and textures. Unlike bare steel, color coated sheets are widely used in architectural, automotive, and consumer industries where aesthetic appeal and durability are essential.

Manufacturing Process of Roofing Sheet

- Roll Coating Process::The cleaned sheet passes through a chemical bath to form a conversion coating (e.g., chromate or zirconium) for corrosion resistance.A primer layer (1–5 μm) is applied via roller to improve adhesion and prevent rust. Common primer types include epoxy or polyester.The main color layer (10–25 μm) is applied using precision rollers. Pigments can be customized for color, gloss, or texture (e.g., matte, metallic, embossed). A protective layer is applied to the reverse side of the sheet to prevent corrosion from the underside.

- Curing:The coated sheet is heated in an oven (180–250°C) to cure the paint, forming a durable, cross-linked polymer film.

- Post-Processing: Some sheets may be laminated with plastic films or protective layers for added scratch resistance (e.g., in appliance manufacturing).The large coils are cut into specified sizes for different applications (e.g., roofing panels, door skins).

Advantages of Roofing Sheet

- Aesthetic Versatility:Customizable colors, patterns, and finishes (e.g., wood grain, stone texture) allow design flexibility for architectural facades, interior decor, or consumer products.Consistent color uniformity across large surfaces reduces painting on-site, saving time and costs.

- Corrosion Resistance:The organic coating acts as a barrier against moisture, chemicals, and UV radiation, while the galvanized steel substrate (if used) provides additional rust protection.Suitable for outdoor applications like roofing, siding, or signage in coastal or industrial environments.

- Cost Efficiency:Pre-painted sheets eliminate the need for on-site painting, reducing labor and equipment costs.Long-lasting coatings minimize maintenance (e.g., repainting) and extend product lifespan compared to bare steel.

- Formability and Lightweight:The coating remains intact during bending, rolling, or stamping, making it ideal for complex shapes in automotive bodies, appliance casings, or HVAC ducts.Lighter than alternative materials (e.g., aluminum) while maintaining structural strength.

- Environmental Benefits:Low-VOC (volatile organic compound) coatings are increasingly used, aligning with green building standards.Recyclable steel substrate reduces environmental impact, and some coatings are designed for easy separation during recycling.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.Convenient Online

Transparent Pricing

Hassle-Free Maintenance

Certified Industry Specialists

Authentic Materials and Components

Convenient Online Ordering

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.