Key attributes

Industry-specific attributes

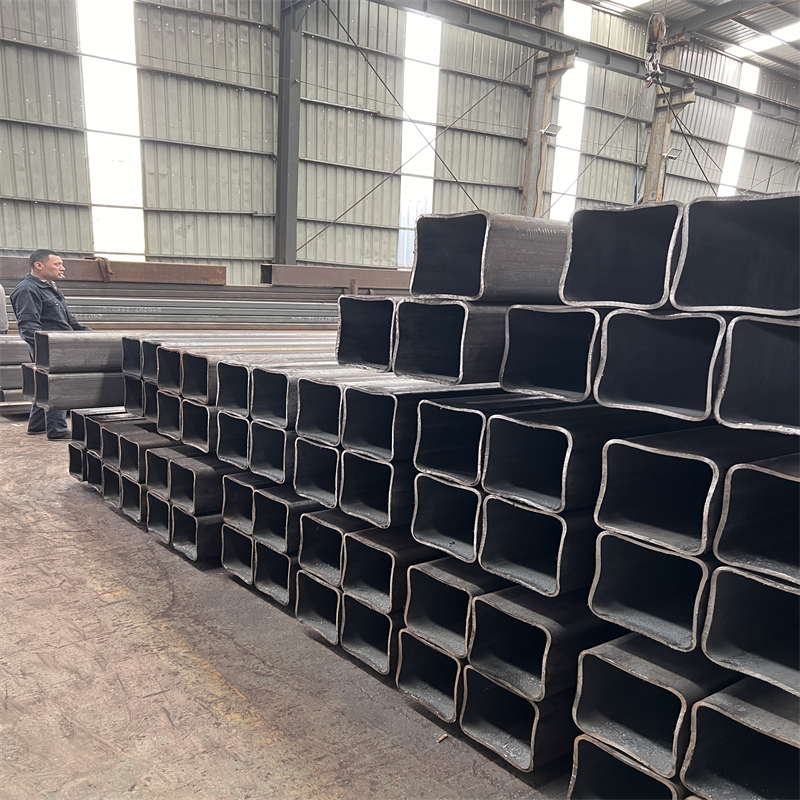

| Section Shape | Square |

| Surface Treatment | |

| Tolerance | ±1% |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by theoretical weight |

Other attributes

| Place of Origin | Shandong, China |

| Alloy Or Not | Non-Alloy |

| Standard | JIS |

| Technique | ERW |

| Grade | Q195/Q215/Q235/Q345, GR.A/B, S235/S355 |

| Delivery Time | 8-14 days |

| Brand Name | kehuan |

| Application | Square Steel Pipes |

| Length | 12M, 6m |

| Certificate | JIS, ISO9001 |

| Processing Service | Welding, Cutting |

| Grade | 10#-45#20#A53-A369A53(A,B)Q195-Q345 |

| Standard | ASTM |

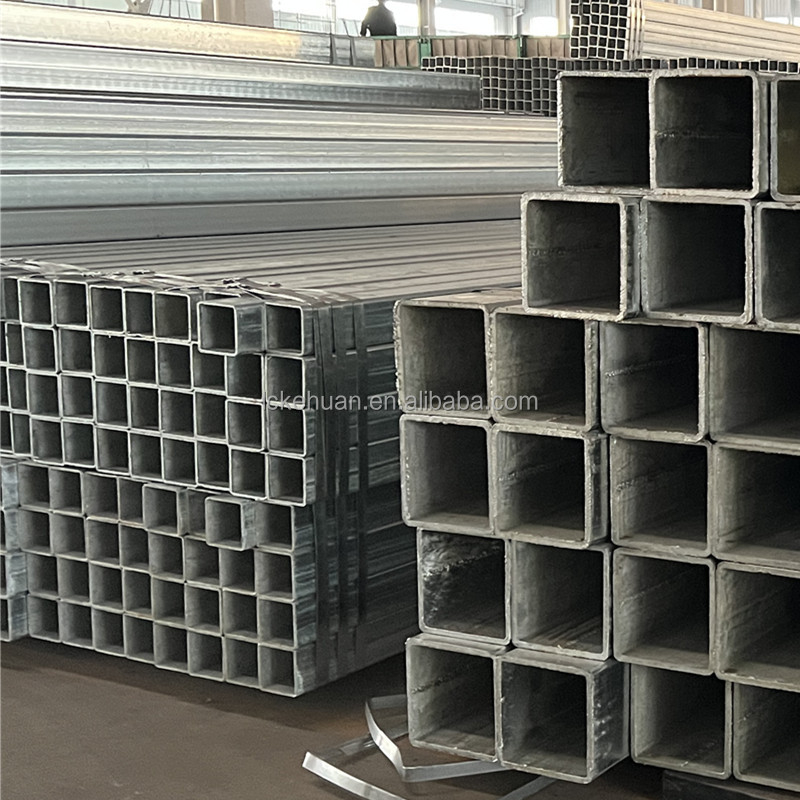

| Product name | Galvanized Square Steel Pipes |

| Surface | Pre-Galvanized/Hot dipped Galvanized |

| Keyword | mild steel pipe |

| Shape | Square Pipe Tube |

| Material | Q195/Q215/Q235/Q345, GR.A/B, S235/S355 |

Specification

| Brand Name | kehuan |

| Application | Fluid Pipe, Hydraulic Pipe, OIL PIPE |

| Alloy Or Not | Non-Alloy |

| Thickness | 1-60mm |

| Standard | JIS |

| Length | 12M, 6m, 6.4M, 3M |

| Certificate | API, JIS, ISO9001 |

| Grade | Mechanical tubes petroleum pipeline |

| Surface Treatment | |

| Tolerance | ±5% |

| Processing Service | Cutting |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by actual weight |

| Delivery Time | 8-14 days |

| Product name | petroleum oil pipe line |

| Usage | transmission of gas .water .petroleum, fence.construction. |

| Keyword | petroleum pipes |

| length | Customers’ Request |

| Packaging Details | Export standard package,bundled or be required. |

| Advantage | Strong Corrosion Resistance |

| MOQ | 5 Tons |

| Service | 24 Hours Online |

| Grade | ASTM A106 A53 API 5L X42-X80, N80 |

Kehuan’s Rectangular Steel Tube is crafted to perfection, meeting rigorous standards. Experience the difference with our exceptional products.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Quality Assurance

Quality Assurance

Certified Inspections

Company Profile

Established in 2011, located in Liaocheng City, Shandong Province

It is one of the largest manufacturers of carbon steel and alloy seamless steel pipes in Shandong Province, China.

Kehuan has four advanced hot rolling production lines Eight expansion production lines and China’s most advanced heat treatment production line.

Interacting with customers

What is Rectangular tubes?

Rectangular tubes are hollow tubular steel materials with a rectangular or square cross-section. They belong to a type of profile and are widely used in multiple fields such as construction, mechanical manufacturing, chemical engineering, and metallurgy.

Manufacturing Process of Rectangular tubes

- Raw material preparation

Selection of materials: Choose appropriate metal materials based on the application, such as carbon steel (Q235B, Q355, etc.), stainless steel (304, 316, etc.), aluminum alloy, etc. The raw materials are usually hot-rolled or cold-rolled steel plates / steel strips.

Pre-treatment: Clean the surface of the plates (remove oil stains, oxide scale, etc.) and cut them to the appropriate width and length according to the pipe diameter specifications. - Forming process

Cold bending forming (commonly used)

Gradually bend the plates into a rectangular profile through multiple sets of rolling rolls. First, the plates enter the rolling machine through the guide rolls, and then are successively compressed by the horizontal and vertical rolls to gradually bend into an open rectangular billet.

The key lies in the design and arrangement of the rolling rolls, which need to be precisely adjusted according to the target pipe diameter to ensure the accuracy of the cross-sectional dimensions and angles.

Hot forming (for special requirements)

For high-hardness or thick-walled materials, the plates need to be heated to a plastic state first, and then formed by pressing into molds to reduce the cold work hardening effect. - Welding (for welded rectangular pipes)

High-frequency welding (HFIW): Heat the edges of the open rectangular billet to a molten state, press it firmly with the extrusion rolls to form a continuous weld seam. It is highly efficient and suitable for mass production.

Argon arc welding (TIG)/ submerged arc welding (SAW): For products with high welding quality requirements (such as stainless steel pipes), use inert gas protection or submerged arc welding, resulting in a smoother weld seam and higher strength.

Unwelded rectangular pipes: Form directly through piercing, hot rolling or cold drawing processes, without welding, suitable for high-pressure, high-strength scenarios (the production process is more complex and the cost is higher). - Shaping and calibration

Gauge straightening: Use a gauge straightening machine to squeeze the welded pipe, correct the cross-sectional dimensions, straightness and edges, and ensure that the pipe diameter tolerance meets the standards (such as GB/T 3094, ASTM A500, etc.).

Straightening: Use a straightening machine to eliminate the bending deformation of the pipe to ensure the straightness in the length direction. - Surface treatment (according to requirements)

Galvanizing: Hot galvanizing (immersion zinc) or cold galvanizing (electro-galvanizing), enhancing corrosion resistance, suitable for construction and outdoor scenarios (such as hot galvanized rectangular pipes Q235B).

Polishing / Passivation: Stainless steel rectangular pipes are often polished or passivated to improve surface smoothness and corrosion resistance.

Coating: Spray anti-rust paint, epoxy resin, etc., to further protect the pipe. - Quality inspection

Dimensional inspection: Measure the pipe diameter, wall thickness, length, diagonal deviation, etc., to ensure compliance with specification requirements.

Mechanical property tests: Tensile test, bending test, flattening test, etc., to verify strength, toughness and ductility.

Weld seam inspection: Non-destructive testing (such as ultrasonic, eddy current testing) to check for cracks, pores, etc. in the weld seam.

Surface quality inspection: Visual or instrument inspection of surface flatness, coating uniformity, etc. - Cutting and packaging

According to customer requirements, cut the pipe into the specified length (such as fixed-length cutting), deburr and clean after that.

Sort and pack according to specifications, mark the material, size, quantity, etc., and prepare for shipment.

Advantages of Rectangular tubes

- I. Structural Mechanics Advantages

- High torsional and bending strength

- The moment of inertia (resistance to bending) and section modulus (torsional performance) of rectangular sections are more directional than those of circular tubes. For example, the bending resistance in the long side direction is stronger, making them suitable for structures subjected to unidirectional bending (such as building beams and supports), and they can provide higher carrying efficiency with the same weight.

- Good stability

- The flat cross-section of rectangular tubes is less prone to rotation or lateral deformation in supporting structures, especially in compression scenarios (such as columns and frames), and the symmetry and edges of the section can enhance structural stability and reduce the risk of buckling.

- High space utilization

- Rectangular sections better meet the requirements of rectangular or square building / equipment spaces, facilitating stacking, installation and layout (such as steel structure frames and curtain wall supports), and reducing space waste.

- II. Processing and Installation Convenience

- Flexible connection methods

- It can be directly fixed with welding, bolt connections, flange connections, etc. to other components, and the sharp edges are convenient for positioning and clamping, with high connection accuracy (such as steel structure nodes).

- Compared to circular tubes, the planar welding surface of rectangular tubes is larger, and the welds are more uniformly stressed, with more reliable connection strength.

- Convenient cutting and hole drilling

- The straight edges of rectangular sections facilitate mechanical cutting (such as laser cutting, plasma cutting) and drilling, with high processing efficiency, and the cuts are smooth, requiring no additional trimming (especially suitable for customized projects).

- Compatible surface treatment

- It can be compatible with various surface treatment processes (such as hot-dip galvanizing, painting, chrome plating), and the coating / coating adhesion at the edges is better (such as the corrosion resistance of hot-dip rectangular tubes is superior to ordinary steel tubes).

- III. Material and Cost Advantages

- Material diversity

- It can be made of carbon steel (Q235B, Q355), stainless steel (304, 316L), aluminum alloy, copper alloy, etc., meeting the requirements of different environments (corrosion resistance, high temperature resistance, lightweight). For example:

- Stainless steel rectangular tubes are suitable for corrosion-resistant scenarios such as chemical and food equipment;

- Aluminum alloy rectangular tubes are often used in aviation and rail transportation due to their light weight.

- Cost controllable

- The production process of welded rectangular tubes (cold bending + welding) is mature, and the cost is lower than that of seamless tubes when mass production is carried out. Moreover, for the same specifications, the material consumption of rectangular tubes is similar to that of circular tubes, but the mechanical performance is better, and the cost performance is higher.

- IV. Application Compatibility

- Architecture and Steel Structures

- Used in industrial plants, bridges, and frame structures of high-rise buildings, as beams, columns or supporting components (such as H-shaped steel as an alternative solution, which is more suitable for customizing section sizes).

- Suspended grilles, scaffolding, door and window frames, etc., taking advantage of the installation convenience and regular appearance of rectangular sections.

- Mechanical and Equipment Manufacturing

- Mechanical arms, conveyor equipment supports, industrial frames (such as automated production lines), using its torsional strength and structural stability.

- In vehicle manufacturing, rectangular tubes are used for truck frames, container skeletons, and engineering machinery chassis, balancing strength and lightweight requirements.

- Decoration and Civilian Fields

- Furniture frames (such as tables, chairs, shelves), interior decoration lines, outdoor railings, etc., with the line-like appearance of rectangular sections better conforming to modern design aesthetics, and the surface can be polished or painted with colored coatings, enhancing the aesthetic appeal.

- V. Other Features

- Sealing and Fluid Transmission

- Although rectangular tubes are not as suitable for high-pressure fluid transmission as circular tubes (the circular section is more conducive to smooth fluid flow), in non-high-pressure scenarios (such as ventilation ducts, cable trays), the rectangular section can provide a larger cross-sectional area and is convenient for installing against the wall.

- Environmental protection and recyclability

- Metal rectangular tubes can be 100% recycled and reused, meeting the environmental requirements of green buildings and industrial production, and the waste tubes can be re-melted into sheets for further processing.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.Convenient Online

Transparent Pricing

Hassle-Free Maintenance

Certified Industry Specialists

Authentic Materials and Components

Convenient Online Ordering

Why Us

- Unmatched Steel Expertise

- Dedicated to Your Specifications

- Premium Quality Materials

- Simplified Ordering Process

- On-Time Delivery, No Compromises

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.