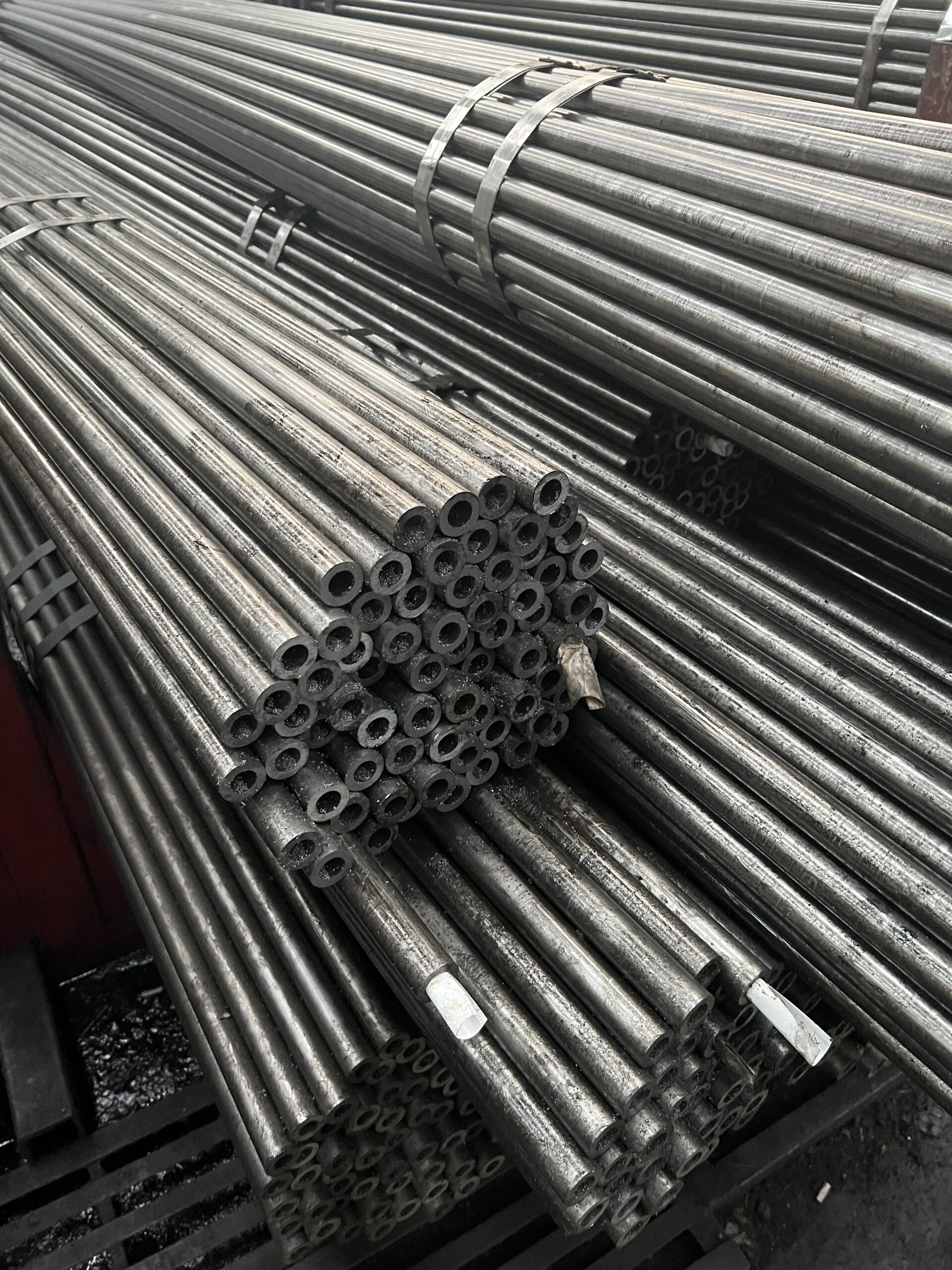

Key attributes about precision Pipe

Industry-specific attributes

| Section Shape | Round |

| Surface Treatment | Hot Rolled |

| Tolerance | ±1% |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by theoretical weight |

Other attributes

| Place of Origin | Shandong, China |

| Alloy Or Not | Non-Alloy |

| Standard | ASTM |

| Grade | S235JRH Ss400 S235jr En10305-3 E235 |

| Delivery Time | 8-14 days |

| Brand Name | Kehuan |

| Application | Boiler Pipe, Fluid Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe |

| Special Pipe | API Pipe, Other, EMT Pipe, Thick Wall Pipe |

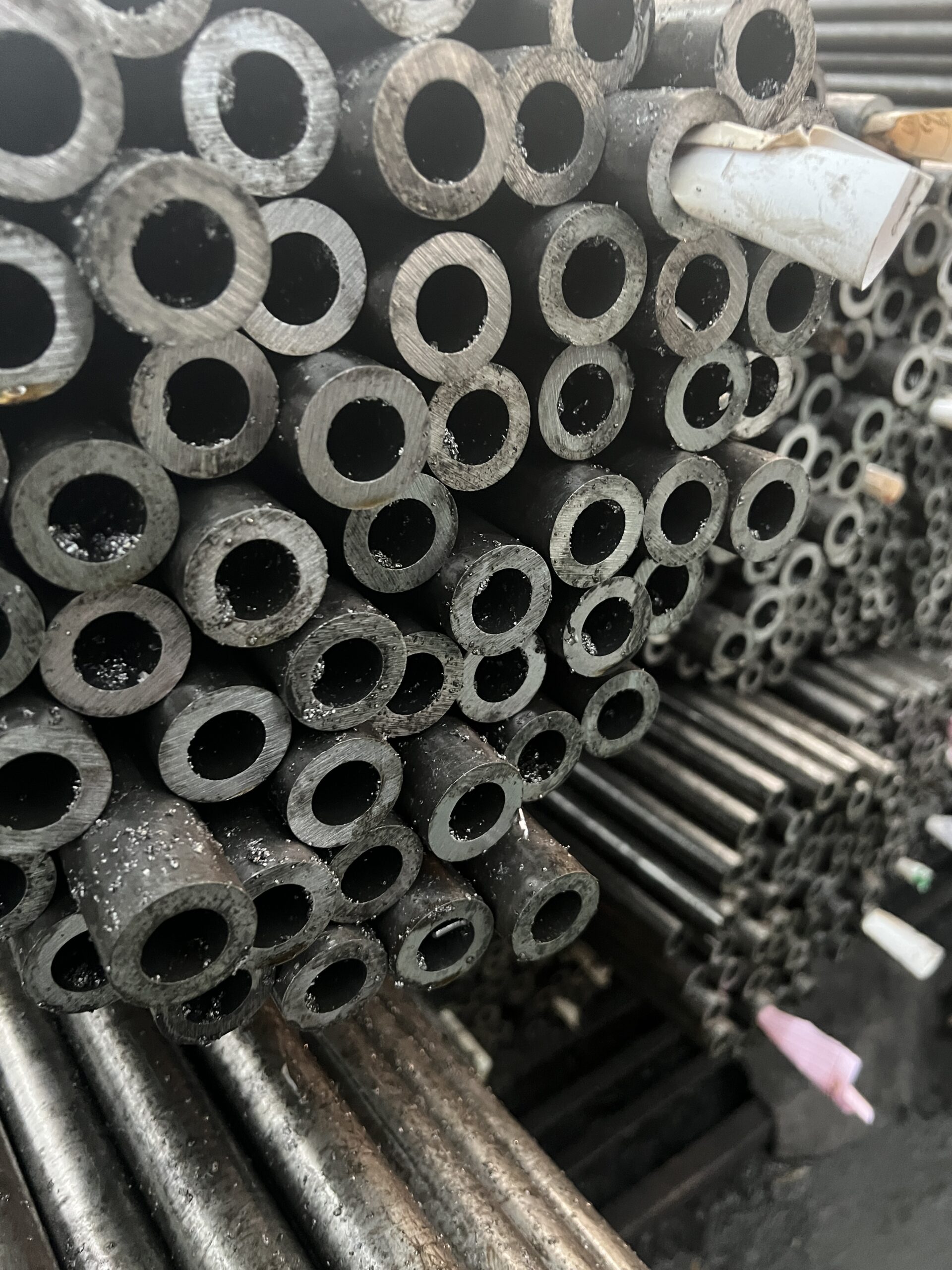

| Thickness | 2-40mm |

| Length | 12M, 6M,,customized |

| Certificate | API , CE, BSI, SASO, JIS, ISO9001 |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Standard | ASTM JIS DIN GB AISI |

| Application | Fluid Pipe, Hydraulic Pipe, OIL PIPE |

| Product name | Precision Pipe |

| Place of Origin | Shandong China |

| MOQ | 1 Tons |

| Wall Thickness | 6mm-70mm |

| Sample | Avaliable |

| Technology | Seamless Hot Rolled |

| Material | 10#.20# 45# 16Mn |

| Payment | TT DP LC |

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Quality Assurance

Quality Assurance

Certified Inspections

Company Profile

Established in 2011, located in Liaocheng City, Shandong Province

It is one of the largest manufacturers of carbon steel and alloy seamless steel pipes in Shandong Province, China.

Kehuan has four advanced hot rolling production lines Eight expansion production lines and China’s most advanced heat treatment production line.

Interacting with customers

What is Precision Pipe?

Precision Pipe is produced with exceptional dimensional accuracy and the absence of welding or seams. It is manufactured by extruding a solid billet through a die to form a hollow tube, a process that yields a pipe with a uniform molecular structure and premium mechanical strength. Unlike conventional pipes, Precision Pipe is engineered to withstand extreme pressure and temperature conditions, making it the preferred choice for critical industrial applications that demand reliability and durability.

Manufacturing Process of Precision Pipe

- Billet Heating:A high-grade steel billet is heated to a precise temperature to ensure malleability without compromising its structural integrity. This step is crucial for maintaining the material’s consistency during subsequent forming processes.

- Piercing:The heated billet is pierced by a mandrel to create a hollow core, forming the basic tubular shape. This process requires advanced machinery to achieve the tight dimensional tolerances that define Precision Pipe.

- Elongation and Rolling:The hollow tube is elongated and rolled through a series of dies to achieve the exact specified dimensions—including inner diameter, outer diameter, and wall thickness. This step ensures the pipe meets strict precision standards for fit and function.

- Finishing:The pipe undergoes rigorous finishing processes, including sizing (to refine dimensions), straightening (to eliminate structural deviations), and heat treatment (to optimize mechanical properties like hardness and ductility). These steps guarantee the pipe’s surface smoothness and resistance to deformation.

Advantages of Precision Pipe

- Superior Structural Strength:The seamless manufacturing process eliminates weak points from welding, resulting in a pipe that can withstand higher mechanical stress and pressure without failure. This makes it ideal for applications where structural integrity is non-negotiable, such as hydraulic systems or high-pressure pipelines.

- Extreme Condition Resistance:Precision Pipe excels in high-pressure and high-temperature environments, maintaining its performance in industries like oil and gas, aerospace, and power generation. Its uniform composition prevents leaks and structural degradation under extreme conditions.

- Consistent Performance:The uniform molecular structure of Precision Pipe ensures consistent performance across all segments, reducing the risk of material variance. This reliability is critical for precision engineering applications where even minor deviations can impact overall system functionality.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.Convenient Online

Transparent Pricing

Hassle-Free Maintenance

Certified Industry Specialists

Authentic Materials and Components

Convenient Online Ordering

Why Us

- Unmatched Steel Expertise

- Dedicated to Your Specifications

- Premium Quality Materials

- Simplified Ordering Process

- On-Time Delivery, No Compromises

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.