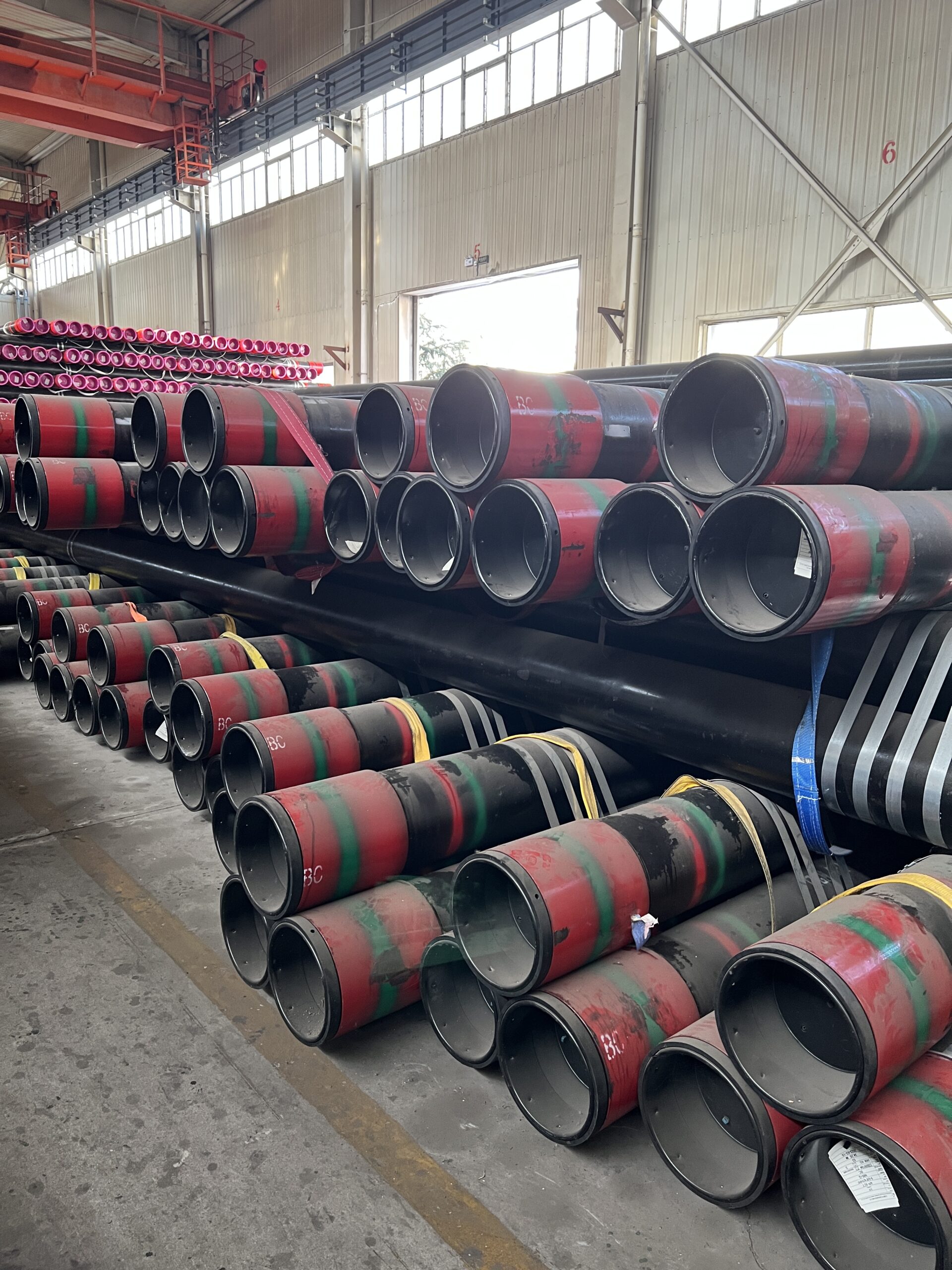

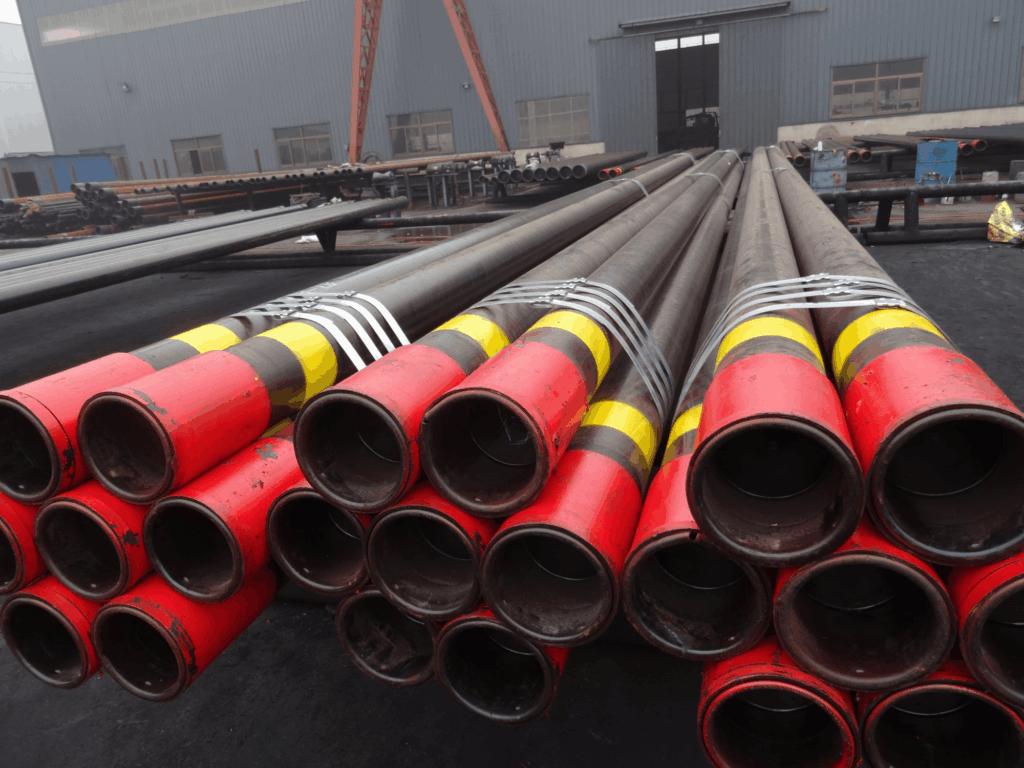

Key attributes about oil pipe

oil pipe Industry-specific attributes

| Section Shape | Round |

| Surface Treatment | Hot Rolled |

| Tolerance | ±1% |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by theoretical weight |

Other attributes

| Place of Origin | Shandong, China |

| Alloy Or Not | Non-Alloy |

| Standard | API 5L、ASTM A106/A53、JIS G3454 |

| Grade | Q235/Q345、API 5L X42-X80、N80 |

| Delivery Time | 15-21 days |

| Brand Name | Kehuan ISO 9001/API Q1 certified enterprise, with 20 years of experience in supplying oilfield pipe materials. |

| Application | Oil and gas transportation, drilling engineering, refining and chemical facilities It is applicable to onshore/offshore oil well casings, gas transmission trunk lines and refinery pipelines. |

| Special Pipe | API Pipe, Other, Thick Wall Pipe |

| Thickness | 6-40mm |

| Length | 12M, 6M, 6.4M,customized |

| Certificate | API , CE, BSI, SASO, JIS, ISO9001 |

| Processing Service | Cutting |

| Grade | ASTM A106 A53 API 5L X42-X80, N80 |

| Application | Fluid Pipe, Hydraulic Pipe, OIL PIPE |

| Product name | petroleum oil pipe line |

| Place of Origin | Shandong China |

| MOQ | 5 Tons |

| Wall Thickness | 6mm-70mm |

| Sample | Avaliable |

| Technology | Seamless Hot Rolled |

| Material | 10#.20# 45# 16Mn |

| Payment | TT DP LC |

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Quality Assurance

Quality Assurance

Certified Inspections

Company Profile

Established in 2011, located in Liaocheng City, Shandong Province

It is one of the largest manufacturers of carbon steel and alloy seamless steel pipes in Shandong Province, China.

Kehuan has four advanced hot rolling production lines Eight expansion production lines and China’s most advanced heat treatment production line.

Interacting with customers

What is oil pipe?

oil pipe (also known as an oil pipe) is a specialized pipeline used in the oil and gas industry for the transportation, extraction, and processing of petroleum products. It plays a critical role in various stages of the oil and gas supply chain, from wellheads to refineries and distribution networks.

Manufacturing Process of oil pipe

1. Raw Material Preparation

- Material Selection:

- High-strength carbon steel (e.g., grades 10#, 20#, 45#) or alloy steel (e.g., 16Mn) is commonly used, meeting standards like API 5L, ASTM A106, or JIS.

- Raw materials are sourced as billets (round steel bars) with diameters ranging from 50mm to 300mm, depending on the final pipe size.

- Quality Inspection:

- Billets undergo chemical composition analysis and ultrasonic testing to ensure no internal defects.

2. Heating and Piercing

- Heating:

- Billets are heated in a furnace to 1,100–1,250°C (2,012–2,282°F) to make the steel malleable.

- Piercing (Hot Roll Piercing):

- Using a piercing mill (e.g., Mannesmann mill), a rotating mandrel pierces the heated billet from the center, forming a hollow tube (referred to as a “shell” or “bloom”).

- The process creates the initial pipe shape with a rough inner diameter.

3. Sizing and Reducing

- Rolling Extension:

- The shell is passed through a stretching mill or elongator to increase its length and reduce wall thickness. A mandrel is inserted inside the shell to shape the inner diameter.

- Sizing:

- A sizing mill rolls the tube to achieve the desired outer diameter (OD) with precision. For smaller pipes, a reducing mill may further decrease the OD while maintaining wall thickness.

4. Heat Treatment

- Normalizing or Tempering:

- Pipes are heated to 850–950°C (1,562–1,742°F) and air-cooled (normalizing) to improve mechanical properties (e.g., strength, ductility) and eliminate internal stress.

- For high-strength grades (e.g., API 5L X65–X80), quenching and tempering (Q&T) may be used to achieve higher tensile strength.

5. Surface Treatment and Finishing

- Deburring:

- Internal and external edges are smoothed to remove burrs from the manufacturing process.

- Cutting to Length:

- Pipes are cut to standard lengths (e.g., 6m, 12m) or customized sizes using saws or laser cutters.

- Surface Cleaning:

- Acid pickling or shot blasting removes rust and scale, followed by coating (e.g., epoxy, polyethylene) for corrosion resistance.

6. Quality Control Testing

- Dimension Inspection:

- OD, wall thickness, and length are measured using calipers and laser scanners.

- Hydrostatic Pressure Test:

- Pipes are filled with water and pressurized (e.g., up to 2,000 psi) to check for leaks.

- Non-Destructive Testing (NDT):

- Ultrasonic testing (UT) or magnetic particle inspection (MPI) detects internal or surface defects.

Advantages of oil pipe

oil pipe offer critical benefits for energy transportation, making them the preferred choice for large-scale infrastructure:

1. High Efficiency in Long-Distance Transportation

- Continuous Flow: Pipelines enable 24/7, uninterrupted transport of large volumes (e.g., millions of barrels of oil per day), outperforming trucks or railcars in consistency.

- Low Energy Consumption: Compared to other modes (e.g., tankers or trucks), pipelines require less energy per unit of fuel transported, as fluids move via pressure or gravity.

2. Cost-Effectiveness

- Long-Term Investment: While initial construction costs are high, pipelines have a lifespan of 50+ years, reducing maintenance and replacement costs over time.

- Economies of Scale: Large-diameter pipes (e.g., 48 inches) can transport massive quantities, lowering the cost per barrel compared to fragmented transport methods.

3. Safety and Reliability

- Contained System: Sealed pipes minimize the risk of spills, leaks, or accidents compared to open transport (e.g., tanker trucks).

- Monitoring Capabilities: Modern pipelines use sensors and SCADA systems to detect leaks, pressure changes, or tampering in real time.

- Robust Design: High-strength materials and corrosion-resistant coatings ensure durability in harsh environments (e.g., extreme temperatures, seismic zones, or offshore waters).

4. Environmental Benefits (Relative to Alternatives)

- Lower Emissions: Pipelines produce fewer greenhouse gases than trucks or ships, as they rely on minimal mechanical power (e.g., pumps) and avoid repeated fuel loading/unloading.

- Reduced Land Impact: Underground pipelines occupy less surface area than roads or rail networks, minimizing habitat disruption.

5. Versatility and Scalability

- Diverse Applications: Suitable for transporting crude oil, natural gas, refined products, or even slurry (e.g., coal mixed with water).

- Expandability: Existing pipelines can be upgraded (e.g., increased pressure) or extended with branch lines, adapting to changing energy demands.

6. Strategic and Geopolitical Significance

- Energy Security: Pipelines provide stable, domestic energy transport, reducing reliance on volatile international markets (e.g., oil tankers vulnerable to geopolitical conflicts).

- Infrastructure Development: They support economic growth by connecting remote production areas to urban centers or export hubs.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.Convenient Online

Transparent Pricing

Hassle-Free Maintenance

Certified Industry Specialists

Authentic Materials and Components

Convenient Online Ordering

Why Us

- Unmatched Steel Expertise

- Dedicated to Your Specifications

- Premium Quality Materials

- Simplified Ordering Process

- On-Time Delivery, No Compromises

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.