Company website

Office website:https://khsteel.net/

Alibaba website:https://lckehuan.en.alibaba.com/

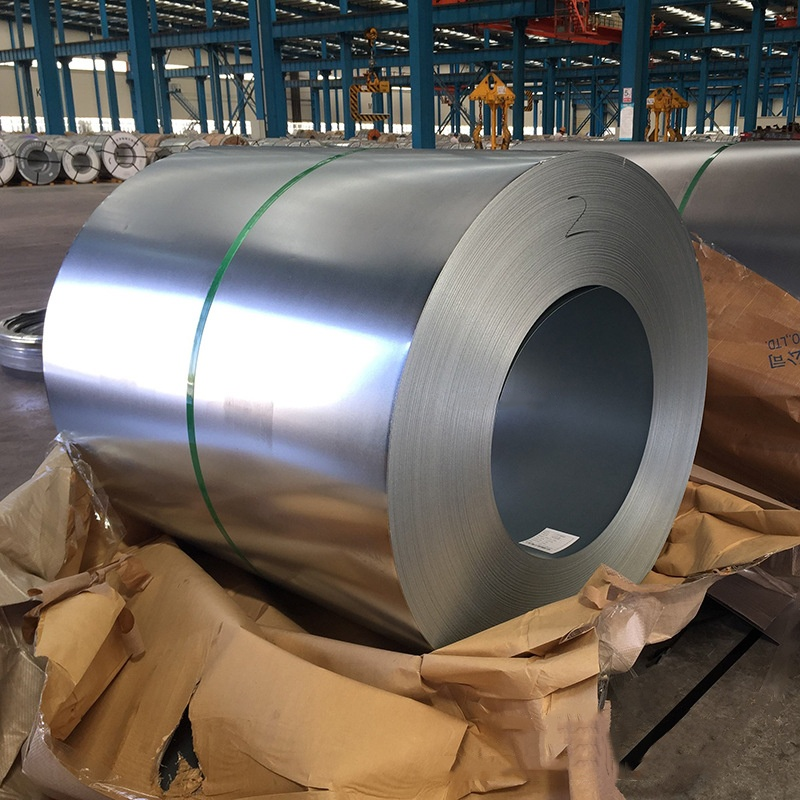

Product parameters galvanized steel coils

| Grade | Q195 Q235 Q345 |

| SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

| SGHC SGH340 SGH400 SGH440 SGH490 SGH540 | |

| DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

| S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD | |

| SS230 SS250 SS275 | |

| Width | 600mm to 1500mm |

| Thickness | 0.125mm to 3.5mm |

| Zinc coating | galvanized steel coils |

| Product | galvanized steel coils |

| Coil ID | 508mm or 610mm |

| Surface treatment | Unoil, Dry, Chromate Passivated, Non-chromate Passivated |

| Spangle | Regular Spangle, minimum Spangle, Large Spangle, Zero Spangle |

| Capacity | 1,500,000MT/year |

| Delivery | 15-25 Days |

| Spangle | Big Medium Small Zero |

| Zinc Coating | 30-275g/m2 |

| Product Name | galvanized steel coils |

| item | value |

| item name | galvanized steel coils |

| Thickness | 0.12-4.0mm |

| Standard | API,ce,tisi,JIS,GS |

| Length | Customers’ Requirement |

| Tolerance | ±1% |

| Delivery Time | within 7 days |

| Product | galvanized steel coils |

| Zinc Coating | 20-275g/m2 |

| Spangle Type | Big spangle,Regular spangle,Mini spangle,Zero spangle |

| Coil ID | 508mm/610mm |

Product Inspection galvanized steel coils

| Standard | AiSi, ASTM, bs, DIN, GB, JIS |

| Thickness | 0.1-200mm |

| Width | 10-2000mm |

| Application | Ship Plate, Building Construction |

| Surface | zinc coated/galvanized |

| Surface Color | RAL/Printed/Matte/Wrinkled/Embossed/Nano |

| Material | CGCC/SGCH/G350/G450/G550/DX51D/DX52D/DX53D |

| Payment name | galvanized steel coils |

| Sample | Provided Freely |

| Trade Term | FOB, CFR, CIF |

| Delivery time | Within 7-30 Working Days According to the confirmed order |

PACKAGE galvanized steel coils

High-purity zinc layer (electro-galvanized layer) cannot form spangles. For example, add tin (<0.5%), solidify at 198°C; add cadmium, solidify at 264°C; add lead, solidify at 317°C; add antimony (<0.3%), solidify at 409°C; or use steam flow or SO2 flow Spraying the surface of the galvanized layer can generate crystallization nuclei early and form large spangles. In fact, spangles are only of ornamental value and have no actual use price. On the contrary, it is not good in terms of anti-corrosion, and the surface appears uneven after painting. Now people ask to minimize spangle or eliminate spangle. In order to obtain small spangles, when galvanizing, when the zinc liquid is close to the solidification temperature, water droplets with a diameter of less than 0.1mm are immediately sprayed on the surface of the galvanized sheet to form small and uniform crystal nuclei, in order to obtain smooth zinc Flowers, and then temper rolling with a reduction of less than 1%. Small spangles are suitable for painting, and smooth spangles are suitable for deep drawing.

| Product Name | Galvanized Steel Coil |

| Type | Coil/Sheet/Plate/Strip |

| Thickness | Hot Rolled Thickness:0.12 ~ 3.00 mmCold Rolled Thickness:1.20 ~ 4.60 mm As Your Request |

| Surface | Mild steel plain finish, hot dip galvanized, color coated, ect. |

| Internatioanal Standard | ISO 9001-2008 / ISO 630 / JIS / ASTM2.0mm-6.0mm |

| Standards | ASTMA53/ASTM A573/ASTM A283/Gr.D/BS1387-1985/ GB/T3091- 2001,GB/T13793-92, ISO630/E235B/JIS G3101/JIS G3131/JIS G3106/ |

| Materials | SGCC/ CGCC/ DX51D+Z |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

| Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

| Width | 600mm-1500mm, according to customer’s requirement |

| ID | 508mm/610mm |

| Coil Weight | 3-20 metric ton per coil |

| Package | clients’ requirement and Standard export sea-worthy packing |

| Another Name | Hot rolled mild steel I beam , I beam , H beam ,steel beam ,beam |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 7-15 workdays after receiving deposit or L/C |

It is mainly used in construction,automotive ,metallurgical and electrical industries In the construction industry,mainly used for making roofs and walls,prefabricated keel,pre-cast bulkhead,doors and windows.In automotive industry ,mainly for body shell, chassis ,doors,fuel tanks, etc In metallurgical industry,mainly used as substrate of PPGI. In electrical in industry,mainly for shell of electrical appliance.Galvanized steel strip is a special process of steel products, its surface is uniformly covered with a layer of zinc. This treatment not only significantly enhances the corrosion resistance of the steel strip, making it able to resist the erosion of harsh environments such as moisture and salt spray, but also extends the service life of the material. Galvanized steel strip is widely used in construction, automobile manufacturing, home appliances, agriculture, communication equipment and other fields, as a structural part, protective layer or conductive components, plays an indispensable role. Its excellent corrosion resistance, machinability and economy make galvanized steel strip become one of the indispensable important materials in modern industry.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.