Angle steel Key attributes

Industry-specific attributes

| Standard | ASTM |

| Grade | S235JR-S335JR Series |

| Type | Equal |

| Tolerance | ±1% |

| Invoicing | by actual weight |

Other attributes

| Place of Origin | Shandong, China |

| Alloy Or Not | Non-Alloy |

| Delivery Time | 8-14 days |

| Brand Name | Kehuan |

| Model Number | S355JR S235JR |

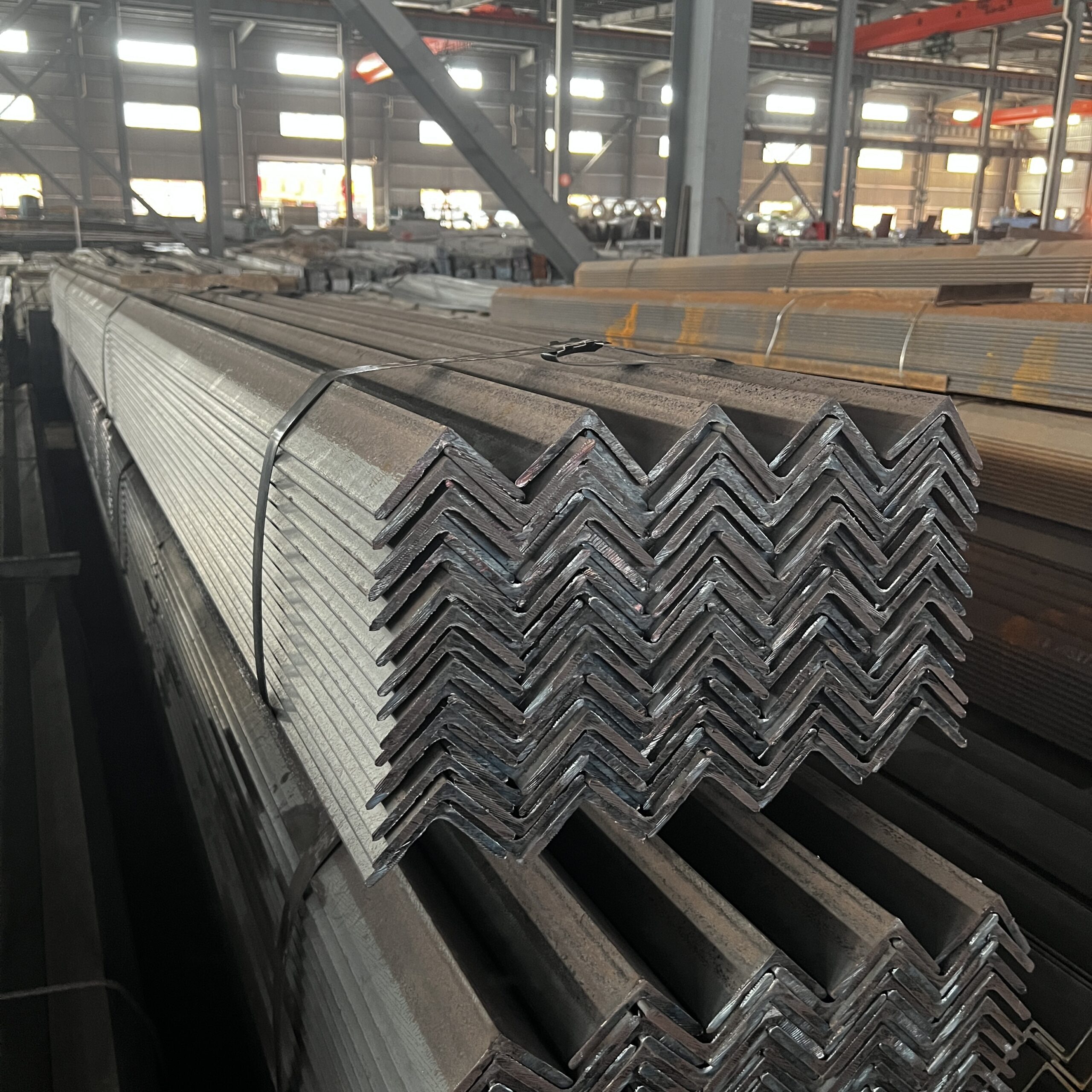

| Application | Structural |

| Processing Service | Bending, Welding, Punching, Cutting |

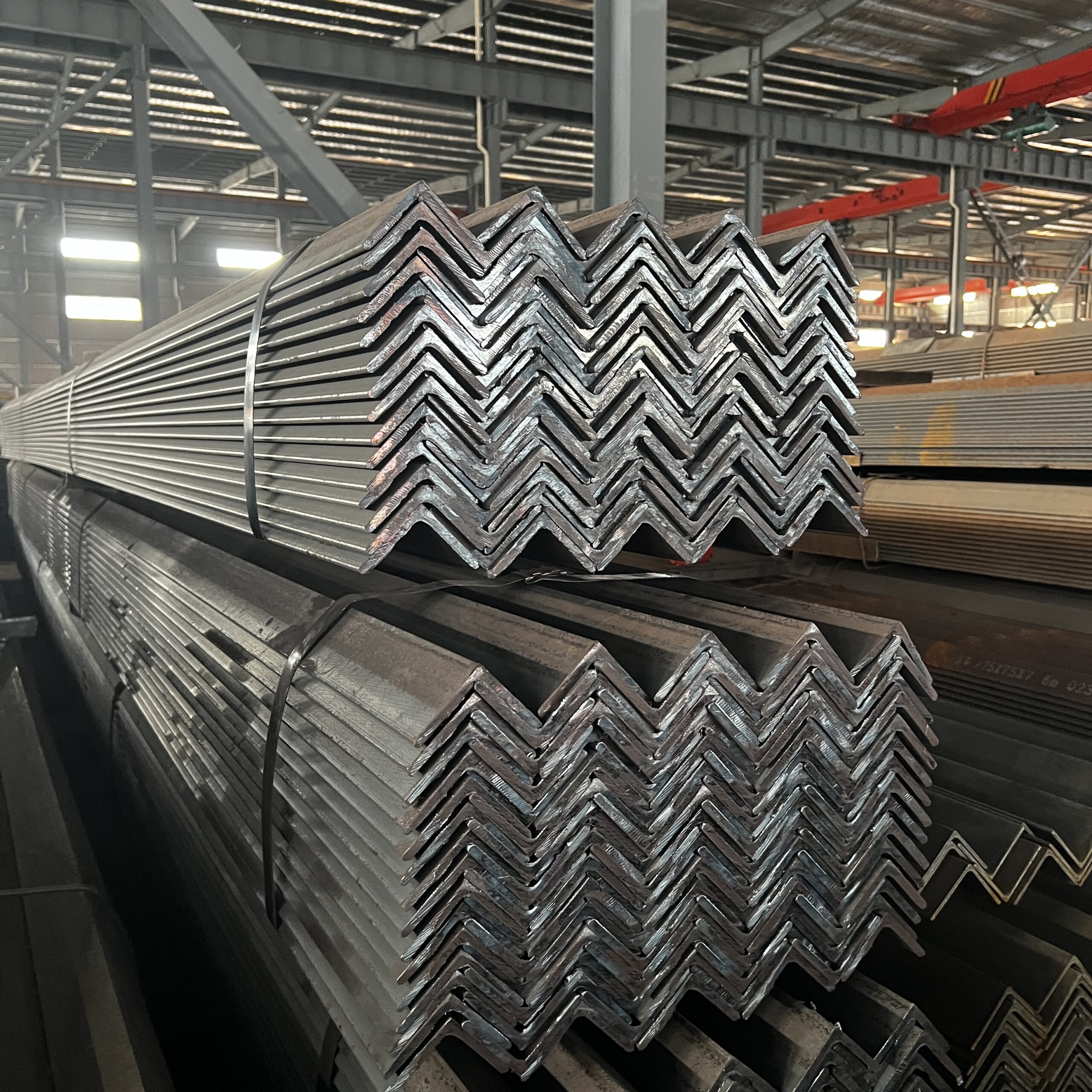

| Product name | Steel Angle Bar |

| Shape | Equal Angle Bar |

| Technique | Hot Rollled |

| Keywords | Angel Steel Bar |

| Standard | ASTM |

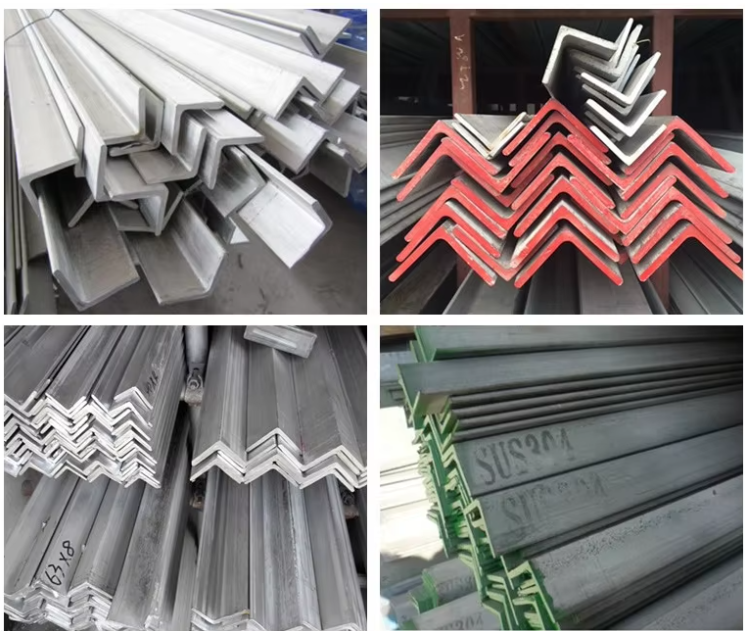

| Surface | Mild Steel Plain |

| Material | Q235/Q345/SS400/ST37-2/ST52/Q420/Q460/S235JR/S275JR/S355JR |

| Surface treatment | Customers’s Requirements |

| Item | Galvanized Steel Angle Iron |

| Length | 6m-12m |

Specification

| item | value |

| Place of Origin | China |

| Shandong | |

| Brand Name | Kehuan |

| Application | Fluid Pipe, Drill Pipe, Gas Pipe, OIL PIPE, Structure Pipe |

| Alloy Or Not | Non-Alloy |

| Section Shape | Round |

| Special Pipe | API Pipe, Thick Wall Pipe |

| Thickness | 0.8 – 30 mm |

| Standard | ASTM |

| Length | 12M, 6m |

| Certificate | API, CE, JIS, GS, ISO9001 |

| Grade | Q195/Q215/Q235/Q345, GR.A/B, S235/S355 |

| Surface Treatment | Pre-galvanized/hot dipped galvanized/Bare/oil |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Punching, Cutting |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by actual weight |

| Delivery Time | 14-21days |

| Standard | GB 5310-1995 |

| Product name | Hot Dip Galvanized Steel Pipe |

| Material | ST37/ST45/ST52/25Mn/27SiMn/E355/SAE1026/STKM13C |

| Type | Welded Steel Pipe |

| Surface | Hot Galvanizing |

| Shape | Round Pipe Tube |

| Usage | Construction Structure |

| Technique | Cold Rolled Hot Rolled |

| Keyword | Galvanzied Steel Pipe |

| Payment terms | T/T |

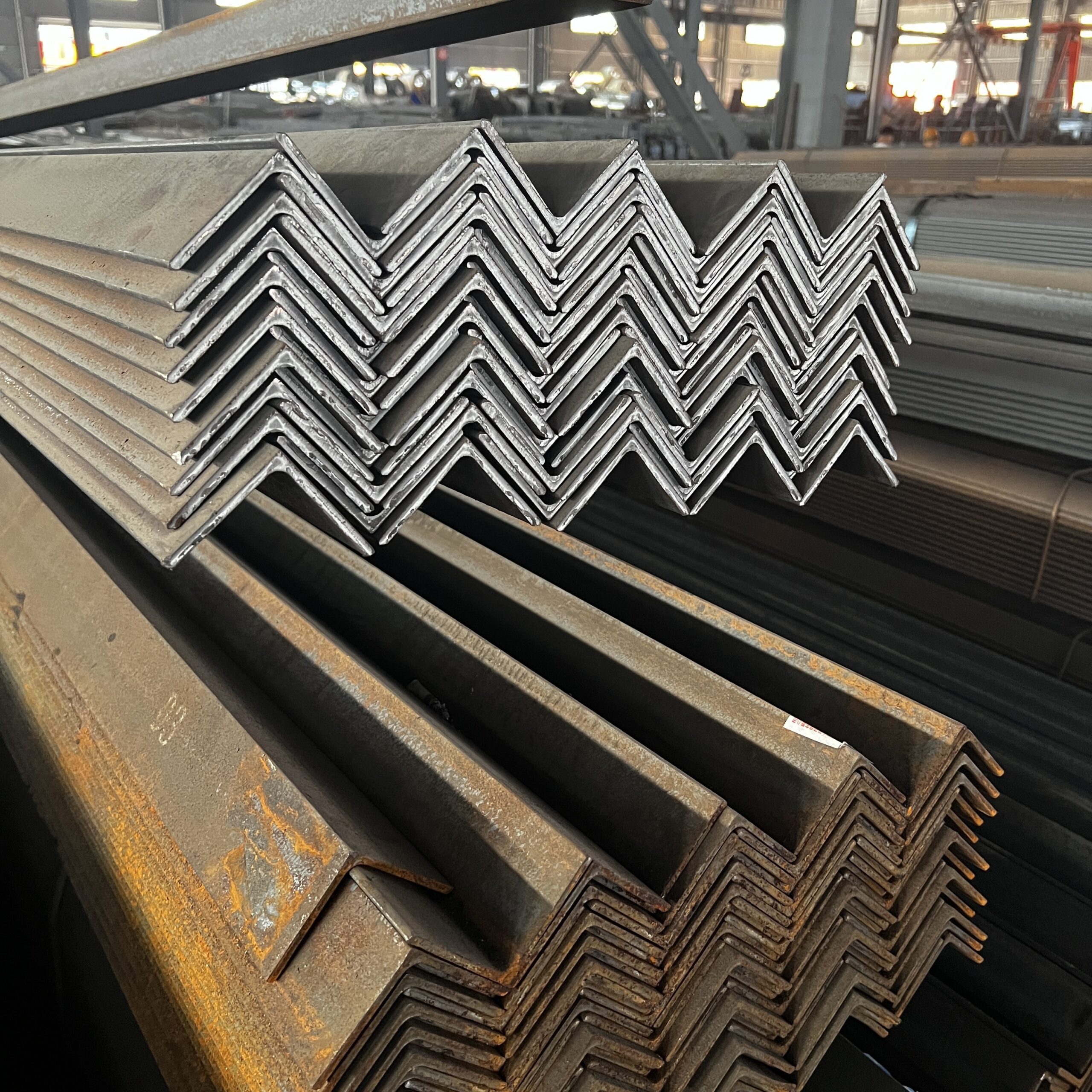

Kehuan’s Angle steel are crafted to perfection, meeting rigorous standards. Experience the difference with our exceptional products.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Quality Assurance

Quality Assurance

Certified Inspections

Company Profile

Established in 2011, located in Liaocheng City, Shandong Province

It is one of the largest manufacturers of carbon steel and alloy seamless steel pipes in Shandong Province, China.

Kehuan has four advanced hot rolling production lines Eight expansion production lines and China’s most advanced heat treatment production line.

Interacting with customers

What is Angle steel?

Angle steel is a long steel bar with a right-angled cross-section. Due to its cross-sectional shape resembling an “L”, it is also called Angle iron. It is a type of steel section that is widely used in industry. Depending on different specifications, materials and applications, it can play an important role in multiple fields.

Manufacturing Process of Angle steel

- Raw material preparationCarbon structural steel, low alloy high strength structural steel and other materials are usually used as raw materials. These steels need to have good mechanical properties and processing performance. Raw materials are generally in the form of steel billets, and the size and quality of the steel billets need to meet the production requirements.

- Heating treatmentThe steel billet is placed in the heating furnace for heating. The heating temperature needs to be precisely controlled according to the material and specification of the steel. Generally, it is heated to 1100-1250 ℃ to make the steel billet reach a red-hot state, which improves its plasticity and facilitates subsequent rolling processing.

- Rolling formingThe heated billets are sent to the rolling mill for rolling. The rolling process is usually divided into two stages: rough rolling and finish rolling.

- Rough rolling: Through several passes of rolling, the billet is gradually rolled into a prototype close to the shape of Angle steel, reducing its cross-sectional dimensions and increasing its length.Precision rolling: Further rolling of the prototype to make its size, shape and Angle meet the standard requirements of Angle steel, ensuring the accuracy and quality of the Angle steel.

- Cooling and straighteningThe Angle steel that has been rolled needs to be cooled, which can be achieved through natural cooling or forced cooling (such as water cooling). During the cooling process, Angle steel may undergo certain deformation. Therefore, it needs to be straightened by a straightening machine to ensure its straightness and verticality.

- Surface treatment and inspectionAccording to the usage requirements, surface treatments such as rust removal, galvanization and painting are carried out on the Angle steel to enhance its corrosion resistance and appearance quality. After the processing is completed, a comprehensive inspection is conducted on the dimensions, mechanical properties, surface quality, etc. of the Angle steel to ensure that the product meets relevant standards and customer requirements.

Advantages of Angle steel

- High structural strength

- The cross-section of Angle steel is right-angled. This structure endows it with high bending strength and rigidity in both directions, enabling it to withstand large loads and making it suitable for structures that need to bear complex stresses.

- Good stability

- Due to the symmetry of its cross-sectional shape, Angle steel is not prone to twisting or deformation under force and has good stability, which can be used to construct stable frame structures.

- Convenient for processing

- Angle steel can be conveniently processed by cutting, drilling, welding and other operations, and is easy to be customized and assembled according to the actual engineering requirements, which can greatly improve the construction efficiency.

- Wide application range

- It can be used in multiple fields such as steel structure frames in construction projects, bridge construction, brackets and support structures in mechanical manufacturing, towers and brackets in power engineering, shipbuilding, and the manufacturing of various industrial equipment.

- Good economy

- The production process of Angle steel is relatively mature, with a low production cost and a high cost performance. Under the premise of meeting the engineering strength and usage requirements, it can save costs for the project.

- Diverse varieties and specifications

- There are various side lengths, thicknesses and materials to choose from. Users can select the appropriate Angle steel specifications based on specific usage scenarios and requirements, offering high flexibility.

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.Convenient Online

Transparent Pricing

Hassle-Free Maintenance

Certified Industry Specialists

Authentic Materials and Components

Convenient Online Ordering

Why Us

- Unmatched Steel Expertise

- Dedicated to Your Specifications

- Premium Quality Materials

- Simplified Ordering Process

- On-Time Delivery, No Compromises

Our Service

At Kehuan, we implement change management strategies specifically tailored to the steel industry, seamlessly integrated into our operations. Our approach not only enhances immediate client benefits but also lays the groundwork for enduring advantages within your existing steel product portfolio.

Customized Product

Tailored solutions for product development to meet specific client needs.

Technical Consulting

Expert guidance on product selection, design optimization, and implementation.

Quality Assurance

Rigorous testing procedures to ensure reliability and performance.

Maintenance Guide

Comprehensive maintenance guides to ensure optimal product performance.

Certified Inspections

Certified evaluations to ensure compliance with industry standards.

24/7 Customer Support

Prompt assistance for inquiries, concerns, and technical issues.

Company Profile

At Kehuan, we excel in providing customized change management strategies specifically crafted for the steel industry. Our seamless integration approach ensures optimization of immediate client benefits while establishing long-lasting advantages within your existing steel portfolio.

Material Selection

Careful selection of high-quality raw materials.

Precision Cutting

Utilization of advanced cutting technologies for precise dimensions.

Forming and Shaping

Shaping raw materials into seamless steel pipes.

Heat Treatment

Application of heat treatment processes for enhanced durability.

Surface Finishing

Finishing processes for improved aesthetics and corrosion resistance.

Quality Assurance

Rigorous inspections to ensure reliability and adherence to standards.

Why Us

Selecting a steel service provider is a crucial decision, impacting the safety and performance of your projects. At Kehuan, we offer unmatched expertise in the steel industry. With years of experience, we possess in-depth knowledge of steel products, ensuring that your projects receive the highest level of care.

Industry Expertise

Reliable solutions backed by extensive industry experience.

Customized Solutions

Tailored options to meet your specific project requirements.

High-Quality Products

Guaranteed superior performance and durability in every product.

Advanced Technology

Precision and efficiency achieved through cutting-edge methods.

Exceptional Service

Prompt assistance and reliable support for all your needs.

Timely Delivery

On-time delivery, ensuring your projects stay on schedule.